About DRIP®

Rapid chemical reactions changing generally available possibilities

Duroplast Reactive Inkjet Printing

Additive manufacturing (3D printing) has a potential to revolutionize almost every aspect of human endeavor. Currently there are a handful of techniques that allow us to form objects via addition of material. Most used techniques utilize material prepared before printing. Which is deposited and either melted, sintered, or hardened to form desired product.

Among the most important of the 3D printing techniques are:

- Fused Deposition Modeling (FDM),

- Selective Laser Sintering or Melting (SLS, SLM),

- Stereolithography (SLA).

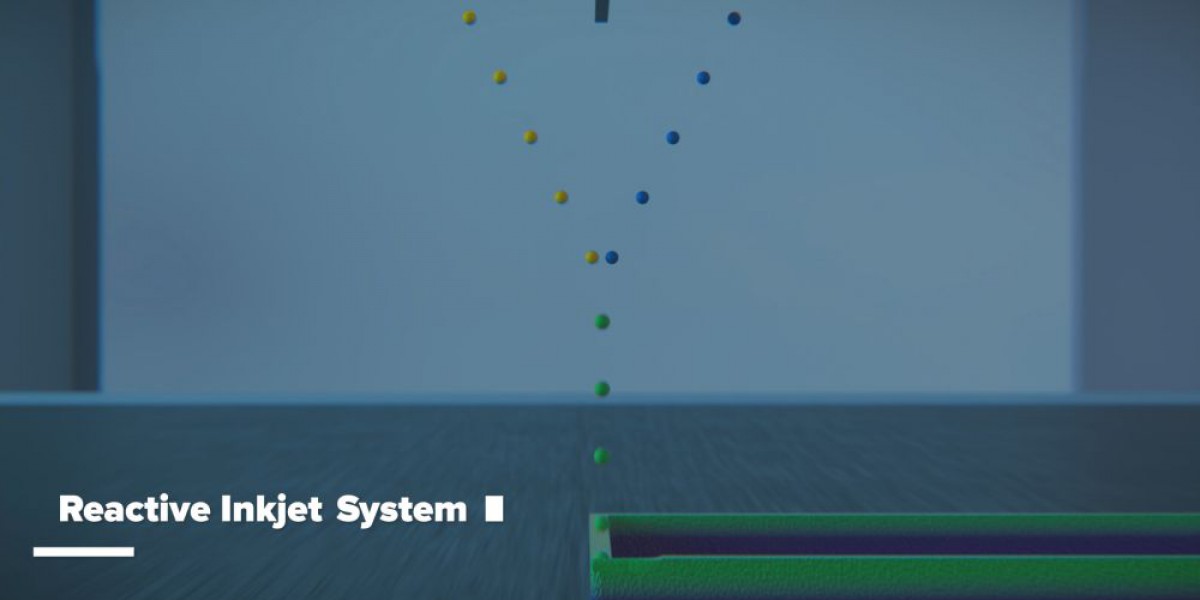

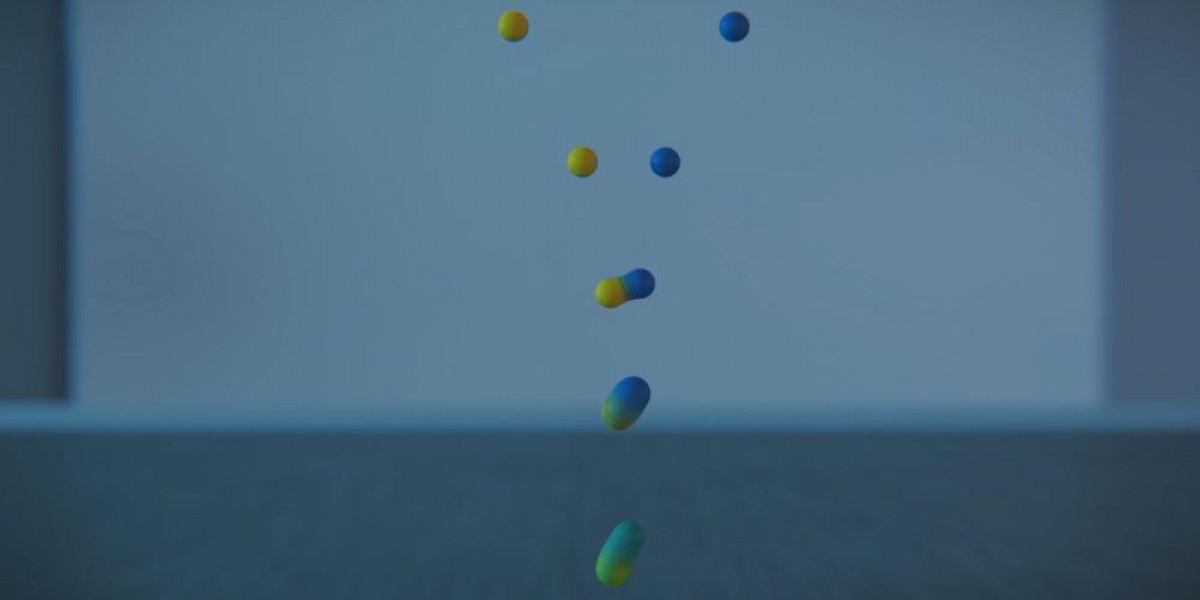

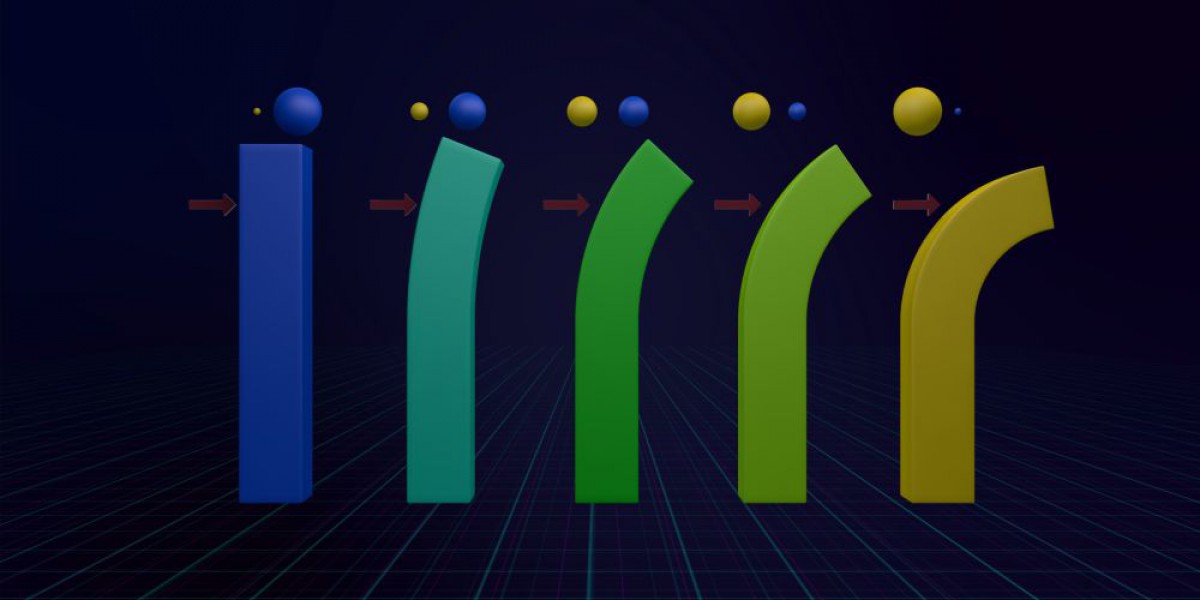

Reactive Inkjet Printing (RIP) is a method in which a material is formed by chemical reaction during the process of deposition. In this way the material is being created during the deposition which allows for online tunning of the material properties. There is no need to use three different filaments, just two that can be mixed in different proportions.

Benefits

Advantages a new way of obtaining 3D structures.

MANY PRINTING POSSIBILITIES

Technique allows for printing with polyureas, polyurethanes, silicones acrylates and many others.

DUROPLAST MATERIALS

Obtained material can be spatially cured allowing for printing with duroplast materials which could not be printed in any other way.

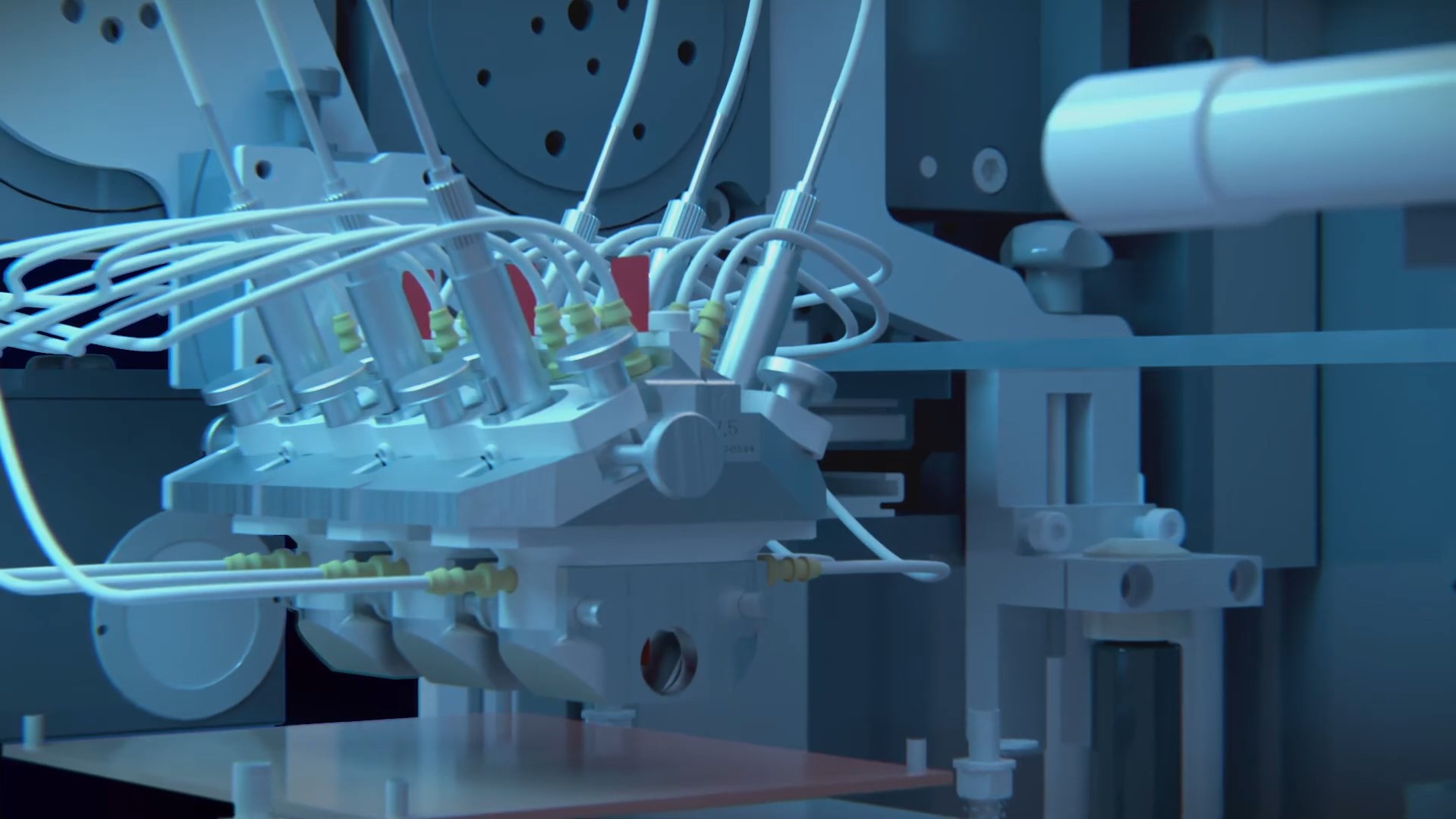

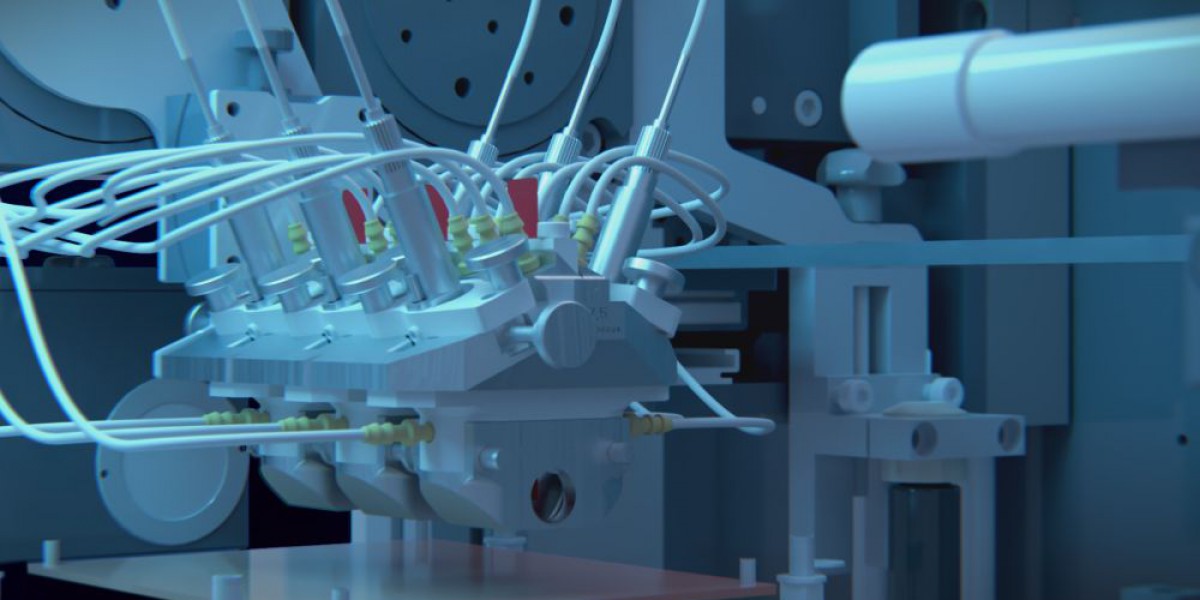

MULTIPRINTHEAD SYSTEMS

Extension allow on diversification of the materials printed during one print run

FUTURE-PROOF PRODUCT

The reactive inkjet printing is gaining momentum and is being implemented in several industrial and research applications.

THE FIRST DEVICE OF THIS TYPE

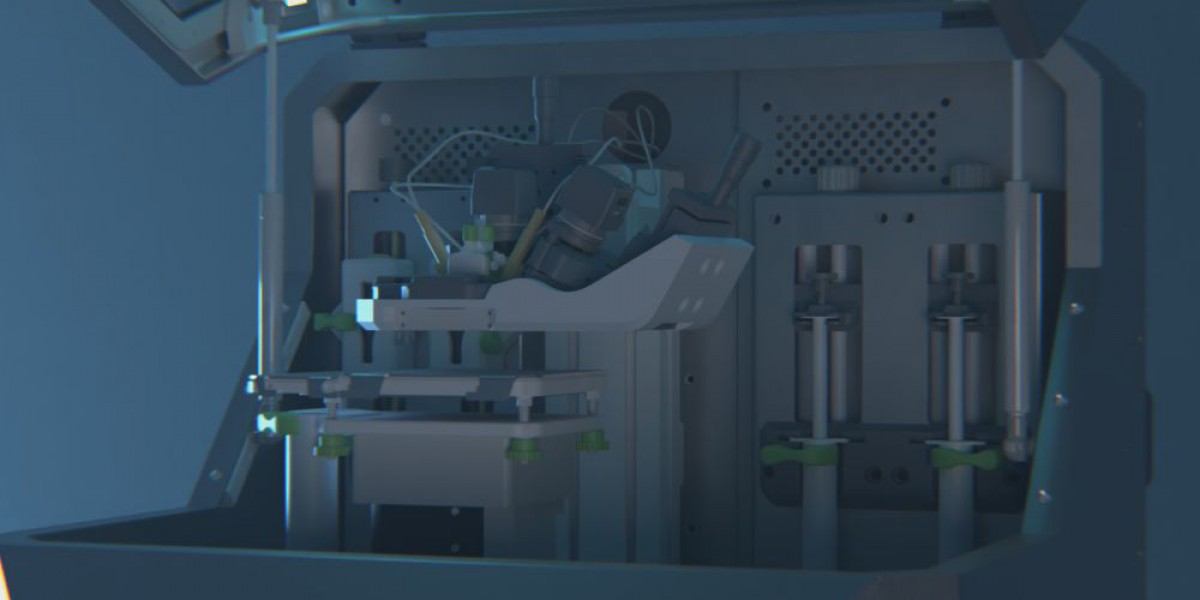

The DRIP Printer is a first commercially available printer capable of printing 3D materials utilizing the reactive inkjet approach.

Revolutionary printing method

Don't waste your time and check out for more about DRIP!

Let’s cooperate

Rapid chemical reactions changing generally available possibilities.

Cooperation

We are looking for partners to further develop the DRIP system in following key pathways:

Enhancing the capabilities of the dispensing systems to widen the array of printable ink formulations, developing novel reactive ink formulations for special applications and showcasing the possibilities of the reactive inkjet technology.

Help us to deliver this extraordinary technology to the market.