About DRIP <sup>®</sup>

DRIP solutions

The RIP (Reactive Inkjet Printing) approach is closely related to the SLA, but unlike the SLA where the liquid ink is solidified by the UV light, in RIP the liquid is solidified by the chemical reaction between different ingredients of the two component ink. Just like 2K adhesives which exhibit excellent material properties. For this reason, RIP does not come with the limitations associated with appliance of the UV light.

How it's working

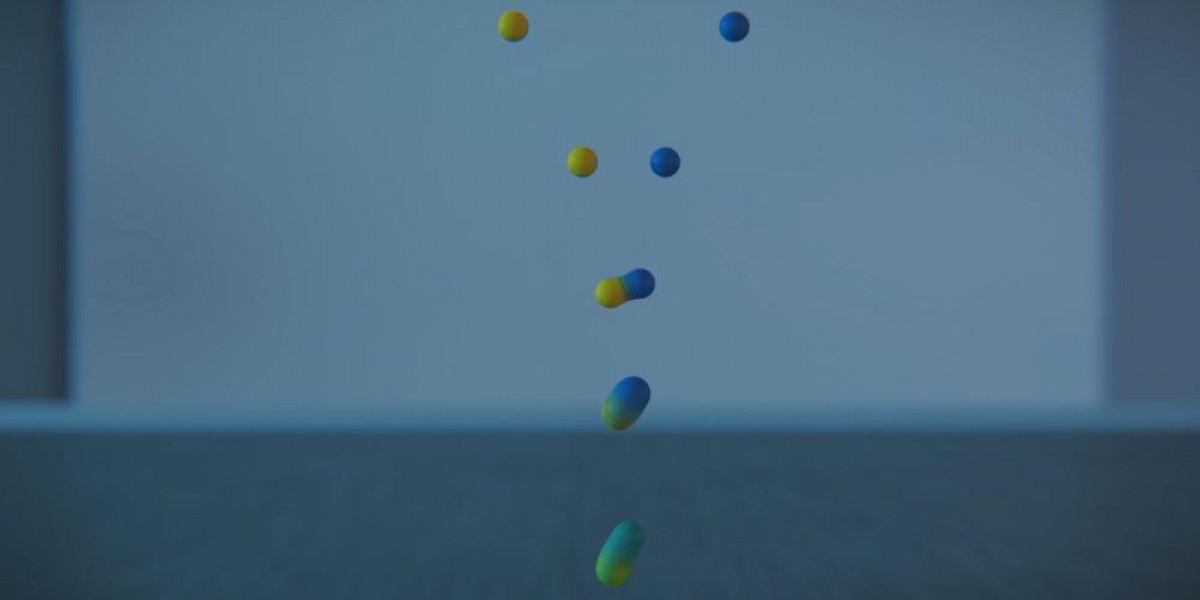

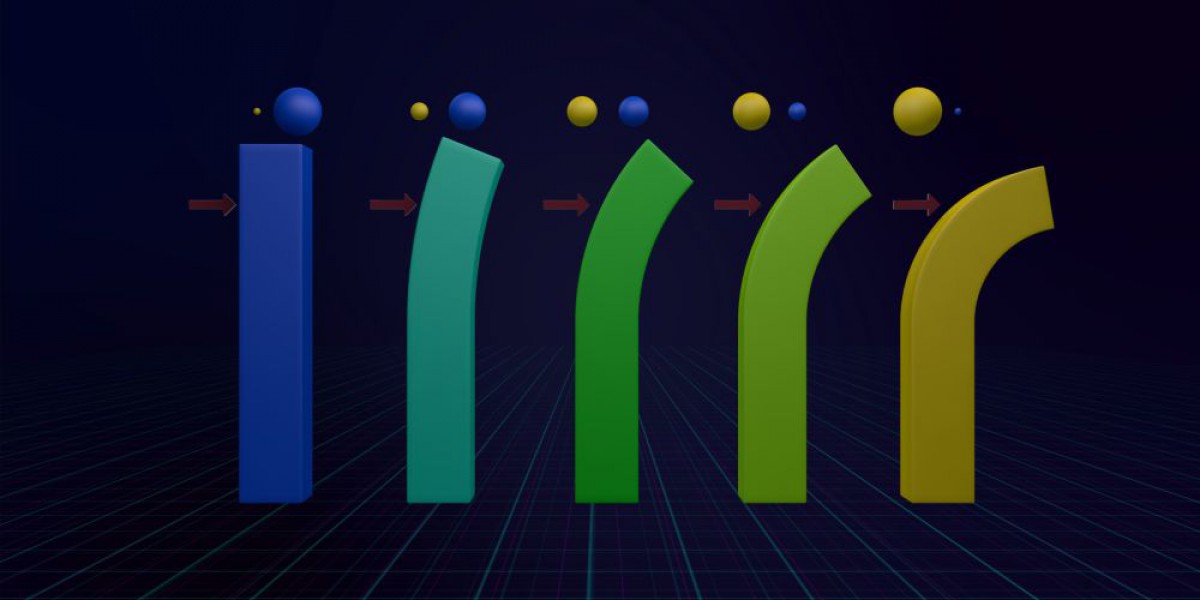

Since the components of the ink are reactive the ink parts must be kept separate. This approach requires specially designed chemical components that will react rapidly to quickly gel the deposited material to allow for building of the product layer by layer. The surface of the gel must be chemically active to allow bonding to the next as well as previous layer. Mixing different components in different proportions allows for obtaining materials with changing parameters i.e. lowering the amount of the hardening agent during the printing process will result with materials with higher elasticity. As we change the proportions during the printing process, we can manufacture products with a gradual change of properties.

This approach can be utilized in 3D printing as well as in 2D printing. In 2D printing ink consists mostly of solvent that needs to either evaporate or sink into the material. Since the deposited material can be colored and does not contain any solvent, RIP can become a chance for solvent-less inkjet printing.

Why DRIP is worth your attention

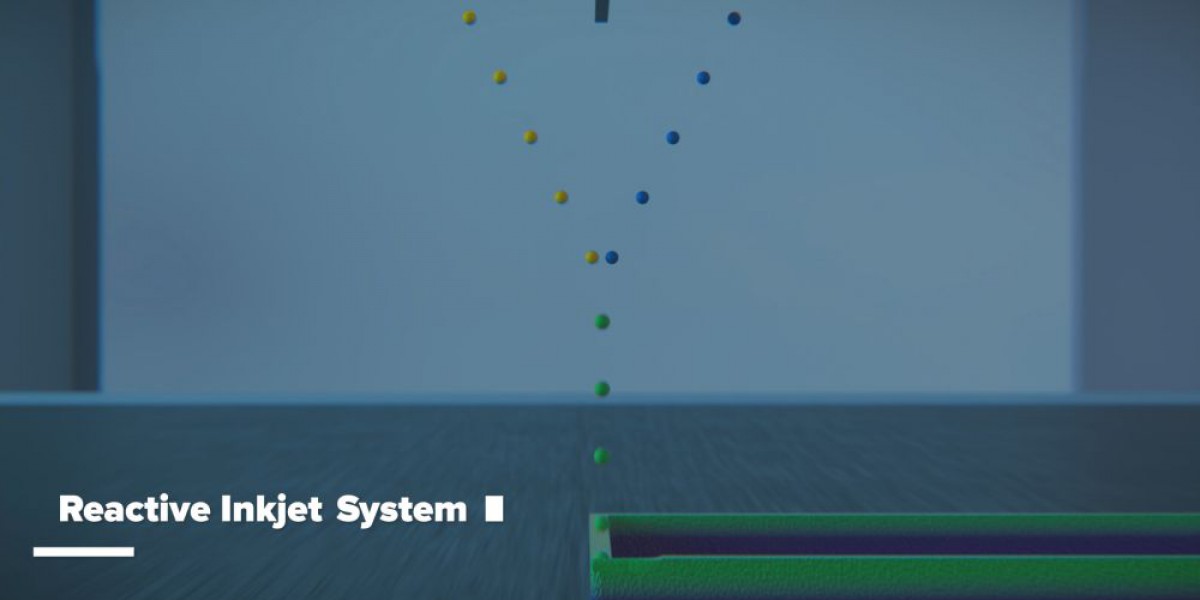

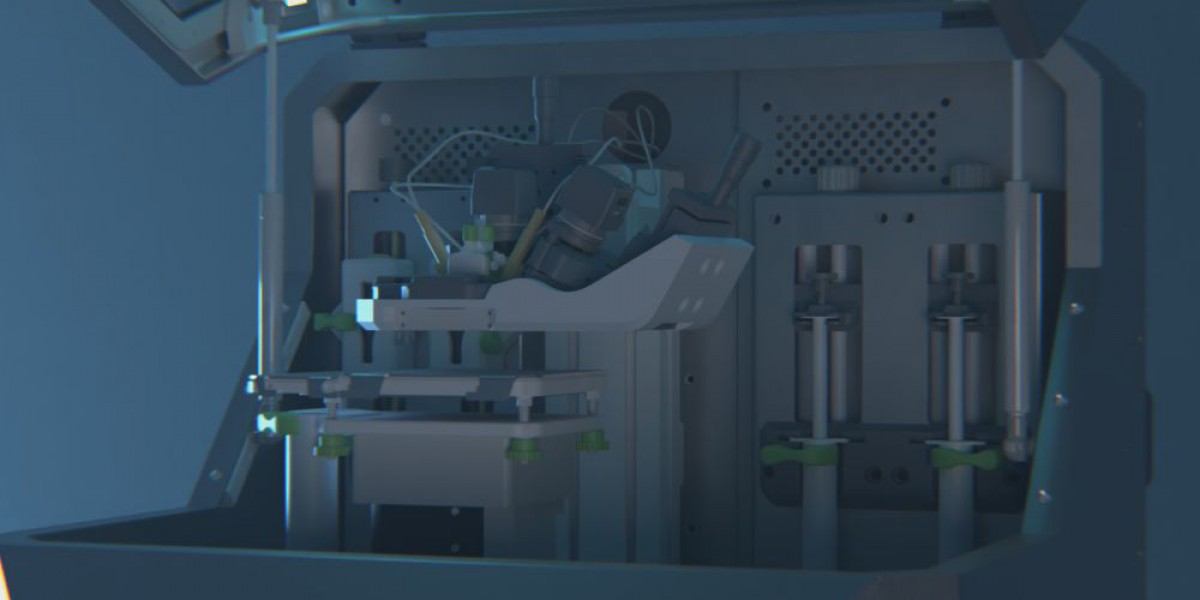

Since the combined inks react rapidly to form a desired material, the true challenge lies in combining the two components in a way that ensures solidification will not occur prematurely clogging the dispenser. In usual approach a layer by layer method is utilized with two reactive inks being printed subsequently. This approach however is limited by the mixing of the components on the surface. With the rapid chemical reaction and subsequent solidification proper mixing must be ensured to obtain homogenous materials of desired properties. To tackle this limitation special solution was developed allowing for inflight mixing of the deposited droplets of reactive inks. The patented DRIP system utilizes special solutions which ensure the sustainable mixing of the two-component system and subsequent deposition on the product with outmost precision.

Our DRIP gallery

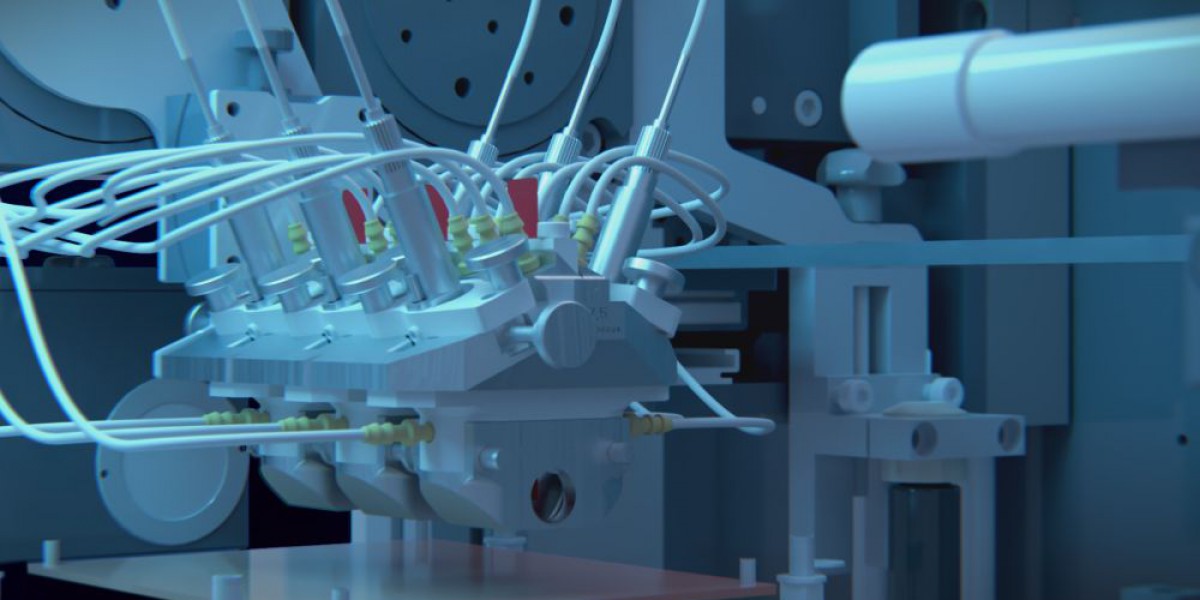

To facilitate such a process requires a specially designed print head.The printhead must perform two tasks. First it must allow for the sustainable combining and mixing of the components, secondly it must minimize the possibility of clogging. This is achieved by a physical separation of the dispensers and continuous washing of the print head with inert gas.The inert gas atmosphere is required when utilizing inks which react with water or oxygen. As in the case of acrylates or isocyanates.

The ability to deposit the droplets of reactive materials exactly where needed, allows for efficient use of materials with minimal waste generation.

More than you think - DRIP applications:

- 3D Modeling – printing structures and devices with an elastic as well as tough construction materials with the ability to gradually change the properties of the printed material to obtain materials with functional gradient of properties. Example: durable bending joints. Mixing of different types of polymers to obtain composite materials which enhance the desired properties of their components.

- Scaffolds for tissue engineering – the ability to print elastic as well as tough biocompatible materials for skin tissue, bone tissue as well as cartilage tissue engineering.

- Printed electronics – printing of conductive as well as resistive layers to obtain a 3D conductive structures. Production of microelectromechanical systems (MEMS). The utilization of transparent conductive as well as resistive layers is applicable in photovoltaics as well as in OLED technologies.

- Research opportunities – the dispensers are tuned to jet a wide array of possible materials. Dispensing tests as well as measurement of the generated droplets parameters allow for precise volume of the chemical reagents deposition on the surface. This approach can be used to produce Drug Delivery Systems with tunable properties, micro-foams for special applications as well as testing of the reaction kinetics in microscale without the need for a solvent or nanoparticle synthesis.